DownTips gives you the best guide on how Electric Furnace works and what is Electric Furnace. Here are some instructions and descriptions are given below.

What is an Electric Furnace?

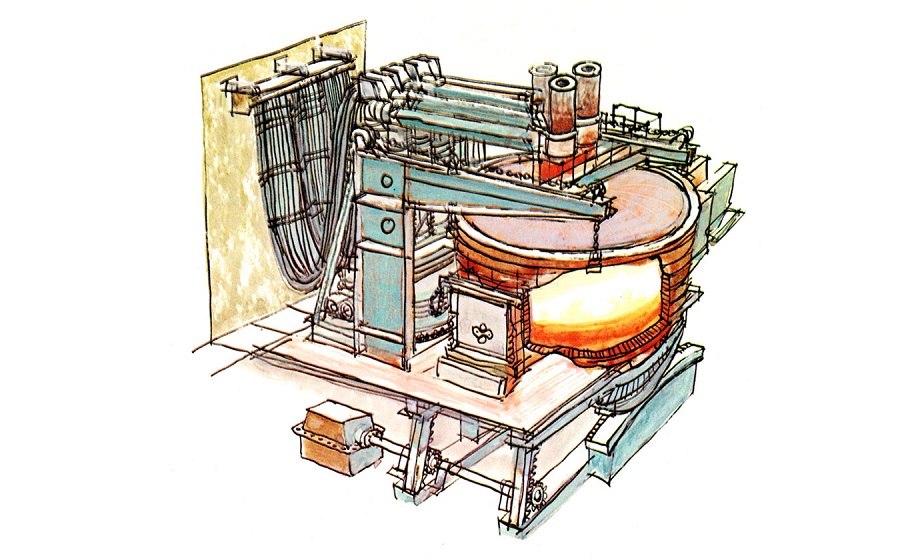

An electric furnace is a heating system that uses electricity to generate heat. It works by converting electrical energy into heat through resistive heating elements. These elements, often made of materials like nichrome or kanthal, heat up when electricity passes through them. The heat produced is then circulated throughout the space using a fan or blower. Electric furnaces are commonly used in areas where natural gas or other fuel sources are not readily available, or where electric heating is preferred for its simplicity and efficiency. They can be used in residential, commercial, and industrial settings for heating purposes.

- Heating Elements: These are the heart of an electric furnace. They are usually made of materials with high electrical resistance, such as nichrome (an alloy of nickel and chromium) or kanthal (an alloy of iron, chromium, and aluminum). When electricity flows through these elements, they resist the current and heat up. The heat generated is what warms the air passing over or around them.

- Thermostat and Control System: The thermostat is the device that measures the temperature in the space being heated. It’s usually placed in a central location and sends signals to the furnace based on the temperature it detects. When the temperature drops below the desired setting, the thermostat signals the furnace to turn on. Once the temperature reaches the set point, the thermostat signals the furnace to turn off. This cycling on and off maintains the desired temperature in the space.

- Blower or Fan: The blower or fan in an electric furnace is responsible for circulating air throughout the system. When the furnace is running, the blower forces air over the heating elements, where it absorbs heat. Then, the heated air is pushed through the ductwork and distributed into the rooms of the building via vents or registers.

- Ductwork: Electric furnaces are typically part of a forced-air heating system, which means they use ductwork to distribute the heated air. The ductwork is a network of metal or flexible tubes that carry the heated air from the furnace to various rooms in the building. Properly designed and installed ductwork is crucial for efficient and even distribution of heat.

- Safety Features: Electric furnaces include various safety features to prevent accidents or damage. For example, they may have limit switches that shut off the heating elements if they get too hot to prevent overheating. Additionally, fuses or circuit breakers protect against electrical overloads by shutting off power to the furnace if the electrical current exceeds safe levels.

- Efficiency Considerations: While electric furnaces are highly efficient at converting electrical energy into heat, their overall efficiency also depends on other factors. Proper insulation of the building, well-designed ductwork, and regular maintenance of the furnace all contribute to its efficiency. Additionally, selecting an appropriately sized furnace for the space being heated is important to avoid energy waste.

Uses of Electric Furnace:

Electric furnaces offer several benefits compared to other heating systems, making them a popular choice for various applications. Here are some of the key advantages:

- Energy Efficiency: Electric furnaces can be highly energy efficient, especially when compared to some traditional heating systems like oil or propane furnaces. They can convert nearly all the electrical energy they consume into heat, resulting in minimal energy waste.

- Clean Operation: Since electric furnaces do not burn fossil fuels, they produce no combustion byproducts such as carbon monoxide, nitrogen oxides, or particulate matter. This makes them environmentally friendly and ideal for indoor air quality, as they don’t emit pollutants or require ventilation for exhaust gases.

- Safety: Electric furnaces are generally considered safer than furnaces that burn fuel, as there is no risk of carbon monoxide leaks or gas explosions. Additionally, electric furnaces often include built-in safety features such as limit switches and automatic shut-off mechanisms to prevent overheating or electrical hazards.

- Low Maintenance: Electric furnaces typically have fewer moving parts compared to combustion-based heating systems, which means they require less maintenance. There are no burners, pilot lights, or fuel lines to clean or repair, resulting in lower maintenance costs over time.

- Ease of Installation: Electric furnaces are relatively easy to install compared to furnaces that require a flue or venting system for combustion gases. They can be installed in a variety of locations, including basements, attics, closets, or even outside if necessary, making them suitable for different building layouts and configurations.

- Zoning Capabilities: Electric furnaces can easily be integrated with zoning systems to control the temperature in different areas or zones of a building independently. This allows for customized heating preferences and energy savings by only heating occupied spaces when needed.

- Quiet Operation: Electric furnaces typically operate more quietly than combustion-based heating systems since they don’t have the noise associated with burners, fans, or ignition systems.

- Long Lifespan: With proper maintenance, electric furnaces can have a long operational lifespan. The absence of combustion-related wear and tear can contribute to their durability and reliability over time.

- Compatibility with Renewable Energy Sources: Electric furnaces can be powered by electricity generated from renewable sources such as solar, wind, or hydroelectric power. This allows homeowners and businesses to reduce their carbon footprint and reliance on fossil fuels for heating.

How electric furnace works?

An electric furnace works by converting electrical energy into heat, which is then distributed throughout a space to provide warmth. Here’s a detailed explanation of how it operates:

- Heating Elements: At the core of an electric furnace are one or more heating elements, typically made of materials like nichrome or kanthal. These elements have high electrical resistance, so when an electric current passes through them, they generate heat. The heating elements are arranged within the furnace housing, usually in a configuration that maximizes heat production and distribution.

- Thermostat Control: The operation of the electric furnace is controlled by a thermostat, which is usually located in a central area of the building. The thermostat monitors the temperature in the space being heated and signals the furnace to turn on or off based on the desired temperature setting. When the temperature drops below the set point, the thermostat sends a signal to activate the furnace. Once the temperature reaches the desired level, the thermostat signals the furnace to shut off.

- Electrical Supply: Electric furnaces require a steady supply of electricity to operate. They are connected to the building’s electrical system through wiring and are usually powered by the main electrical panel or circuit breaker. The electrical current flows through the heating elements, causing them to heat up and generate warmth.

- Air Circulation: Once the heating elements are activated, a blower or fan within the furnace forces air over or around the heated elements. As the air passes over the hot surfaces of the heating elements, it absorbs heat and becomes warm. The blower then circulates this heated air throughout the furnace and into the ductwork connected to the building’s ventilation system.

- Distribution System: The heated air is distributed throughout the building via ductwork or vents. The ductwork is a network of metal or flexible tubes that carry the warm air to different rooms or areas of the building. Vents or registers in each room allow the heated air to enter, raising the temperature and providing comfort to occupants.

- Safety Features: Electric furnaces typically include safety features to prevent overheating or other hazards. These may include limit switches that shut off the furnace if it reaches a certain temperature, as well as fuses or circuit breakers to protect against electrical overloads.

- Thermal Efficiency: Electric furnaces can achieve high thermal efficiency because they convert nearly all the electrical energy they consume into heat. However, the overall efficiency of the system also depends on factors such as insulation, ductwork design, and thermostat settings.